v-belts

V-BELTS FOR DISTRIBUTORS

In our computerized workshop at Moltech, Hungary we design and produce tailor-made industrial solutions for conveying and power-transmission. We are specialized in manufacturing industrial belts, in all sorts and all sizes, standard and non-standard. Thanks to our flexible technology for distributors we manufacture v-belts immediately upon order. Why wait longer? The customer deserves it!

Our production technology makes belts in 4 different categories:

- Transmission belts

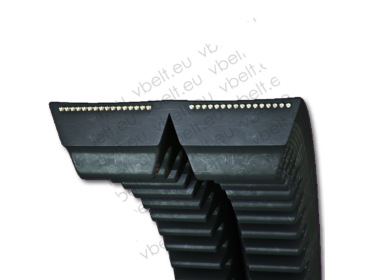

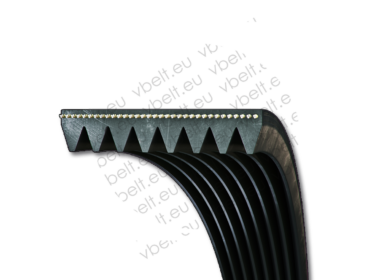

- Coated belts (v-belts, poly-v belts, multiband) for conveying purposes

- Top-pressure belts for edgebander and sawing machines (wood processing industry)

- Caterpillar belts for cable-pulling or haul-off machines (tubes and cable industry)

V-BELTS FOR OEMs

StarkLine belts are running on large industrial machines in a variety of industries: edgebander belts in woodprocessing, haul-off belts in cable manufacturing and power-transmissinon belts in food, agriculture, mining and construction industries. For machine builders we manufacture tailored power-transmission v-belts exactly to the machine engineering specifications. The machine deserves it!

Applicability

- enabled environmental temperature from -55 to 80 Cº

- recommended maximum belt speed - 40 m / sec

- lconditionally not suitable for clutching applications

- conditionally suitable with external ioner pulley

Belt speed: conventional v-belts allow max. belt speed of 40 m/sec. Over 90% of industrial machines around the world work with belt speeds of 20 to 30 m/sec. STARKLINE optimum belt speed is 25 m/sec.

Clutching applications: STARKLINE belts perform best under constant straining and similar speed between pulleys. Certain applications (mostly agro-machines) require different speeds between driver pulley and the driven pulley. In such case of clutching the belt is than sliding on the pulley which causes extreme increase of heat. Extreme heat unfortunately causes deformation and stretching of the material and leads to malfunctioning of the belt.

Tensioning pulley: Most driving applications need 2 pulleys for effective power transmission. Certain belt-driven applications however require a 3rd pulley for optimal tensioning. In normal cases these tensioning pulleys work inside-outward, but if applied conversely it damages the topcover of the belt which shortens the lifetime of the belt.